In Refining process, after centrifugation white sugar contain about 1.5% of humidity (Moisture). In order to decrease its moisture, white sugar is passed through dyers. In this equipment sugar is contacted normally in cross flow with hot air. Moisture will migrate from the sugar to the air. In some dryers, near the outlet zone, sugar is contacted in a co-flow way with cold air in order to decrease dried sugar temperature.

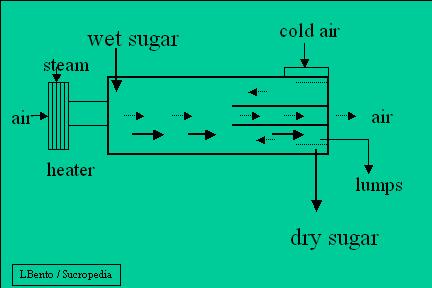

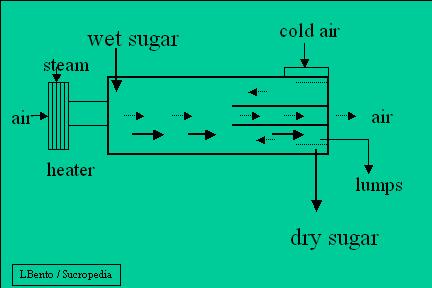

Scheme of a sugar drying with cooling

This dryer consists in a rotating cylindrical drum containing in the inside wall small pads that elevate the sugar during rotation. When sugar falls contacts with the hot air current. The pads are positioned in such way that sugar is displaced horizontally along the drum. In the drying/cooling system air entering the dryer is removed through a pipe placed inside the dryer at the outlet end. Cold air is added to the dryer, after filtration, at the drum end. By this way at the end of the dryer sugar is contacted with cold air and a temperature decrease will occurs. Before sugar is discharged from the drum a screen will remove the lumps in the sugar.

After drying sugar moisture must be lower than 0.05% and temperature lower than 40 oC.

Air entering the dryer must be clean and with a low moisture content.

Other sugar dryers are the Fluidized Bed dryers. In these dryers, sugar is fluidized in a bed of hot air, as it dislocates through the dryer.

Bibliography

Meadows D., 2000, refined sugar drying, conditioning and storage, in Handbook

of Sugar Refining, Ed. Chung Chi Chou, John Wiley & Sons, Inc.

E 0034