Areado SugarBy Bento, Luis San Miguel

Posted on 2007-07-14 Last edited on 2018-11-16

Yellow areado sugar is a traditional sugar product in Portugal. The technique for its production may be original from the East, possibly at XVII or XVIII century (Silveira, 1969). Yamane, 1963, describe the manual process to make this kind of sugar, named in old China, Shan Tang. The same process, as described by this author, was maintained in Portugal till the sixties of XX century in the north of Portugal.

The Portuguese introduced the production of this subgar, in Brazil, named locally amorfo sugar. This kind of sugar was maintained as the main sugar product till the seventies of last century. In the past this sugar was sent from Brazil to Flandres in wood boxes (caissons, in french), given origin to the name Cassonade (Histoire Naturelle du Cacao et du Sucre, 1719). This designation is maintained in Belgium actually.

The manual way to produce araedo sugar was changed in the beginning of last century, in Lisbon. This change included the utilization of vacuum pan and a vacuum stirrer named Areador.

Typical analysis of Yellow Areado Sugar

| Total sugars |

96 - 97 %

|

| Invert Sugars |

0,4 - 0,6 %

|

| Humidity |

1,5 - 2,5 %

|

| Ash |

0,5 - 1,0 %

|

| Colour IU |

2.000 - 2.500

|

Yellow areado sugar (typical analysis in Table) is produced with a mixture of carbonated liquor and refining syrups (Bento, 1983). This mixture is crystallized in a vacuum pan, normally without seeding. The feed is concentrated till the labile zone, sobresaturation higher than 1,30 (Chen, 1993). At this concentration, crystals are spontaneously formed, without seeding for nucleation. By this process, a great amount of small crystals are formed. After crystals formation, massecuite is heated till 105º C to 110º C. This heating is achieved by introducing air in the pan, breaking the vacuum. The hot massecuite, at 95 º brix, is discharged into the Areadores.

The areador is a vacuum mixer where the crystallization proceeds.

After the massecuite charge , vacuum is increased in the areador. A flash evaporation occurs and syrup sobresaturation (in crystals syrup layer) increases. This provokes sugar crystallization. As crystallization is an exothermic process, crystallization heat, 107,6 J/g, at 90ºC (Nicol et al., 1978), is released and massecuite will heat. This heating provokes more evaporations that provokes more crystallization. This chain process stops when impurities in syrup are high enough to prevent more crystallization. This phenomenon was named transformation (Nicol et al., 1978). As a consequence of this effect, massecuite is transformed in small sugar crystals, with a syrup layer, and 3.5% of moisture. This residual moisture depends on feed mixture purity and on concentration and temperature of discharged massecuite (Bento, 1983). The transformation process takes about 15 minutes. After sugar formation, areador is discharged, and sugar is dried and cooled by passing hot and cold air during sugar conveying. Rotary dryers can also be used in this type of sugar.

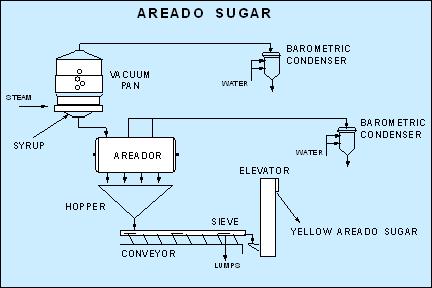

Scheme of Yellow Areado Sugar production

It is important that this kind of sugar be packaged at a temperature lower than 40ºC. At higher temperatures, moisture migration can occur inside the package, due to temperature gradients.

As a consequence of this, sugar can cake inside package.

Due to the quick crystallization occurred in the areador, amorphous sugar is formed in the crystals syrup layer. Later, during storage, this sugar can crystallize and trapped water will be released. This water will wash the crystals and white spots are formed in the yellow sugar (Bento, RAR Internal Report). The formation of these white spots is higher as sugar purity increases. Therefore, to avoid this phenomenon purity of feed syrup must be as low as possible.

Bibliography

Bento L.S.M., 1983, The production of areado sugar at RAR Refinery - Portugal, Proc. of S.I.T. Conf., 222-

241

Chen J.P.C., 1993, The chrystallization of sugar, in Cane Sugar Handbook, Ed. J.P.C. Chen, C.C. Chou, Pub.

John Wiley & Sons, 12aed., 226-312

Nicol W.M., Vane G.W., Daniels M.J., 1978, A continuous process to produce transformed sugar, Proc. of

S.I.T. Conf., 396-409

Silveira J.C., 1969, Monografia do acucar areado, Anais do Instituto Superior de Agronomia, Vol. XXXI,

Lisbon

E0043/53

Comment on this entry

|

|

|